Mass production enables people around the globe to acquire food, clothing, housing, medical supplies, cars, and much more. In other words, it helps people survive and evolve. Today, manufacturers can quickly meet consumer demand and make a profit at the same time. Meanwhile, consumers save money because mass production is efficient.

Mass production was conducted as early as the 6th century BC by the Phoenicians in making bricks with a vast labour force. Mass production was advanced in the United States in the 19th century by employing the principle of interchangeability.

With the principle of mass production, standardized parts are produced within a specified tolerance; a product can be made up by assembling a set of parts selected randomly.

What is Mass Production?

Mass production or flow production is the manufacturing of large quantities of standardized products, often using assembly lines or automation technology. Mass production facilitates the efficient production of a large number of similar products. Mass production is the manufacturing of large quantities of products using efficient methods.

For Example:

Henry Ford, the founder of the Ford Motor Company, developed the assembly line technique of mass production. In 1913, he pioneered the moving assembly line for the production of the Ford Model T automobile.

The main characteristics of mass production are:

- Specialized machines on the assembly lines

- Interchangeable parts for quick maintenance.

- Division of labor

Principle of Mass Production

Economies of Scale

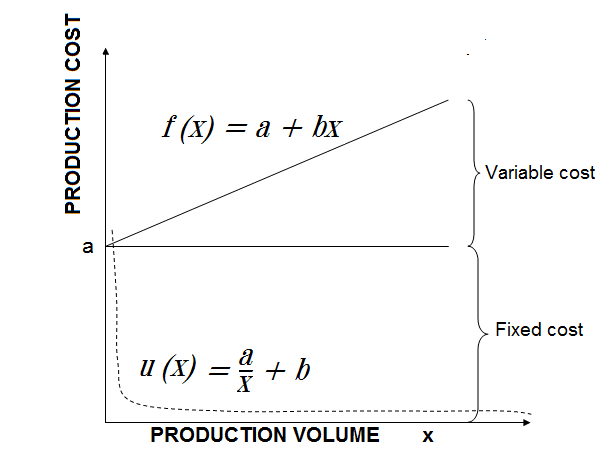

If the fixed cost is a and the unit variable cost is b, then the total cost producing the amount x is:

ƒ(x) = a + bx

and the average unit production cost :

u(x) = (a/x) + b

which decreases with an increase of production volume x, resulting in economies of scale or scale merit. This is an advantage of mass production.

Six-tenths Factor

In-process/chemical industries the fixed cost is not constant; it is usually given by a.xβ where a is a constant depending upon the production method. β is also a constant and takes a value of around 0.6 empirically; hence it is called the ‘six-tenths factor’.

So, The total production cost consisting of the fixed and the variable costs increases with the production volume, while the unit production cost decreases.

Subadditivity Condition

Suppose that a total x of a single product is produced by N firms, each producing xi (i = 1, 2, . . . . . . . . . . N ) and x in total, then xi < x hence from u(x) = (a/x) + b,

u(x) < u(xi)

Multiplying this equation by x, and summing with respect to i, we get:

ƒ(x) < ∑ƒ(x) integration limit (i = 1, 2, . . . . . . . . . . N )

This expresses the subadditivity condition, which means the effect of production accumulation.

Optimum Production Scale

Optimum Production for the Silberston Curve

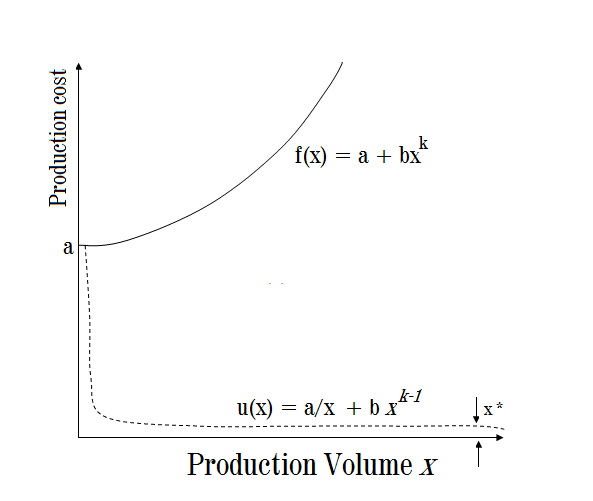

If the total production cost shows non-linearity, differing from f(x) = a + bx, then

for example

f(x) = a + bxk

where k> 1 (increasing returns). Then the unit production cost is:

u(x) = (a/x) + bxk-1

With an increase of production volume x this unit cost decreases at first; it is minimum when

x* = [a/ (k-1)b]1/k

The unit cost increases thereafter.

The production volume which minimizes the unit cost is the optimum production scale. This phenomenon was first discovered in car production. The diagram which indicates this mode is called the ‘Silberston curve’.

The total production cost with increasing returns holds the optimum production scale where the unit production cost is minimum— the Silberston curve.

The Advantages of Mass Production

Most people use mass-produced products daily such as clothes, many packets food items, electronics products, automobiles vehicles, etc. There are many advantages to mass production, some of the advantages of mass production are as follows:

Increased productivity:

Mass production manufactures large volumes of products in less time with high productivity.

Uniformity:

Mass production helps ensure each product is the same. As a result, manufacturers have greater control over the quality, and consumers know what to expect.

Higher quality:

When handmade products are expensive, people can save money by using mass-produced high-quality products. Since each product is the same so the consumer gets quality products.

Faster production:

Manufacturers can develop and produce products much faster using mass production techniques. This means they can beat their competitors in a race to distribute and market new products,

Less error:

Machines are designed to perform specific tasks, and they are less likely to make mistakes than humans during production.

Industrial safety:

Mass production manufacturers generally employ automation technology or a safer work environment to avoid industrial accidents.

Disadvantages of Mass Production

Since mass production has many advantages but it also has some disadvantages as follows:

Less flexibility:

Specialized machinery used in mass production is designed to do one specific job. If there’s a quality issue in production or company want to produce another product. Then production management may have to redesign their process. This can be costly.

Setup costs:

It takes a lot of capital to make a mass-production industry because Specialized machinery and factory floor space to hold assembly-lines and adaptive robotics cost a lot of money.

Inventory :

Mass production creates large quantities at once, so excess inventory requires a large amount of warehouse space which costs money.

Lack of product uniqueness:

Since Each and every product is the same, many consumers want customized products that feel personal while manufacturers do not have the capabilities to mass-produce custom goods.