Industrial equipment or industrial machines are widely used in the manufacturing of various products using labor, machines, tools, chemical, and biological processing, or formulation. Industrial Equipments also used for material handling, industrial safety, Material storage, packing, Waste management, and industrial transportation.

Classifications of Industrial Machines or Manufacturing Equipment

Industrial manufacturing equipment may be categorized in many ways i.e. according to size, type of industry, method of actuation, and by the purpose of machine/ equipment. Those categories are as following:

Industrial machines or Equipment can be classified according to size:

-

Portable equipment (weighing less than 20 kg)

This category includes the machines that we can use from one place to another without using heavy transportation equipment, usually weighing less than 20 kg, such as vernier calipers & other measuring equipment, contour measuring machines, hand grinders, etc.

-

Light duty (weighing less than 1 tonne)

This category includes industrial machines that weighing less than 1 tonne, such as Spot welding machine, Press Machines, Light Machine tools such as small Lathe machine, drill machine, Milling Machines, Coordinate measuring machine, Profile Projector, Robotic Arms, conveyors, Forklift, power transformers, etc.

-

Medium duty (1 to 10 tonnes)

This category includes industrial machines that weighing between 1 tonne to 10 tonnes, such as Injection Moulding Machines, VMC Machine, CNC Lathe machine, Power Generators, Induction Furnaces, Shot Blast Equipments, Industrial Robotic equipment, Boilers, Storage tanks, etc.

-

Heavy duty (above 10 tonnes)

This category includes industrial machines weighing between 1 tonne to 10 tonnes, such as Electrostatic precipitators, Cooling Industrial reactors, Oil Industries machines, Effluent treatment plant, Mining machines, etc.

Classification of industrial machines according to the method of Actuation:

-

Manually operated Equipment

Manually/Hand operated machines operated by very skilled operators. These machines cant be preprogrammed for their processes. Manual manufacturing machines include standard lathes, Surface /cylindrical grinder/ Centerless grinders, Milling machines, Traditional welding machines, etc. There are also some very large capacity machines.

-

Semi-Automatic equipment

Semi-Automatic machines operate by the combined activities of man and machine. these machines are pre-programmed for their specified process but still, need operators to feed and monitoring. Semi-Automatic manufacturing machines include some industrial packaging machines, Additive manufacturing machines, VMC & CNC machines, semi automatic-welding machines, Pet blowing machines, etc. Generally, there are very large capacity machines and produce very high-quality products.

-

Fully Automatic equipment

Fully-Automatic machines operate by itself at a very speed production rate and generally covers two or more than two manufacturing operations. these machines are pre-programmed for their specified processes & need no operators to feed. Fully-Automatic manufacturing machines include some industrial food packaging machines, sensor or photo technology sorting machines, bottling plants, Advanced Paper Printing machines, etc. These machines & equipment are very essential for Industry 4.0

Classification according to the type of product/industry:

- Textile machinery

- Agriculture machines

- Fuel production/refineries machinery

- Steel or other metal industries machines

- Automotive parts/assembly machines

- paper or printing industries

- Food processing industries

- Power industries machines

- Pharmaceuticals machines

- Electrical equipment manufacturing machines

- Plastic, PVC, PU industries machines

- Cement or other building materials industries machines

Classification of industrial machines according to the Power Sources:

-

Electric Motor Operated Industrial Machines:

Electric Motor Operated Machines include machines that operate by an electric motor. Examples: Milling machine, Lathe Machine, Drilling Machines, etc.

-

Engine Operated Machines:

Engine Operated Machines include machines that operate by an engine. Generally, these machines are vehicles that widely used for transportation. Examples: Fork Lift, Crane Machines, Railway engines, etc.

-

Hydraulic Machines

Hydraulic machines use liquid fluid power to perform work. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled manually or automatically by control valves and distributed through hoses, tubes, and/or pipes. Most of the construction machines are the example of hydraulic machines like hydraulic cranes, excavator & hydraulic Press machines, etc.

-

Pneumatic Machines

A pneumatic system is a collection of interconnected components using compressed air to do work for automated equipment. This work is produced in the form of linear or rotary motion. Examples: riveters, forging presses, paint sprayers, rock drills, pavement breakers, blast cleaners, etc.

-

Water/Wind power

A water/wind turbine is a rotary machine that converts kinetic energy and potential energy of water or wind into mechanical work. Water/ wind turbines widely used for industrial power prior to electrical grids.

-

Solar Power

Solar power machines use sunlight or heat from the sun (thermal energy) to produce electricity or to provide Hot water or air to other industrial use. Examples: Solar thermal power stations, Solar vehicles, photovoltaic power stations, etc.

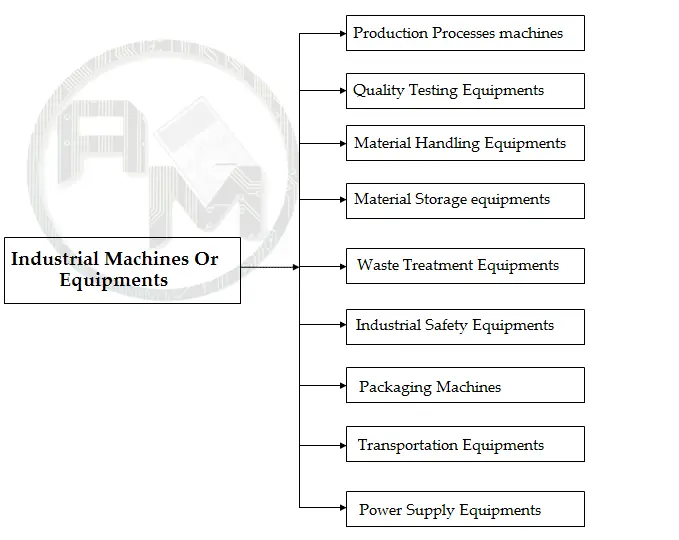

Classification according to the purpose of the industrial machines:

The Industrial machines may be categorized into nine categories according to the purpose of that machine.

Production Processes Equipment

There are different machines for manufacturing processes such as follows:

- Mold making machines, furnace, and molten metal handling machines, Injection Molding machines, Blow Molding machines, etc for the forming processes for metals & plastics.

- Machining tools, CNC machines, etc for machining operations

- Press Machines, Press tools, Forging dies for stamping and forging processes.

- Dyeing machine, Yarn spinning & Fabric machines, Fabric texture, and inspection machines for textile manufacturing processes.

- Ceramic mixture grinder, Ceramic casting, and press machines for the ceramic industry.

Quality testing equipment

To survive in a competitive business environment, goods, and services produced by industry should have the minimum required quality. Thus, Quality inspection instruments and equipment are very necessary. Some examples are as following:

Rockwell Hardness testing machine, Profile Projector, Co-ordinate measurement machine, the Profile scanning machines, surface roughness testing machines, Vernier calipers, Micrometer, Bore gauge for Metal components, or parts.

Material Handling/Storage Equipment

Material handling & storage equipment used in movement, protection, storage, and control of materials and products throughout manufacturing, warehousing, distribution, consumption, and disposal. As a process, material handling incorporates a wide range of manual, semi-automated, and automated equipment and systems that support logistics and make the supply chain work.

Some Material handling machines are fork-Lift, Jet Hand Pallet jack, Conveyor Belt, Adaptive Robots, etc and material storage equipment are Food storage Freezers, Storage tanks, Racks, etc.

Waste treatment machines

Industrial manufacturing and commercial operations create wastes that are very dangerous for our eco-system and industrial pollutant treatment is an increasingly critical topic of discussion. Industrial activities are a major source of air, water, and land pollution So waste treatment machines specially designed for their types of pollutants such as Air treatment plant, Water treatment plant, shredders, waste separator, sewage treatment plant, etc.

Industrial Safety equipment

Industrial safety equipment includes sensors ( such as optical sensors, digital Opto sensors, analog Opto sensors, miniaturized single & multibeam light barriers, piezo-electric sensors, eddy current sensors, acoustic emission sensors & Collision awareness Sensors) Machine Guards, Fire safety mechanisms, respiratory protection, and personal safety equipment such as hand gloves, shoes, and glasses.

There are lot of machine categories such as Packing equipment, Industrial transportation machines. Power supply or power backup machinery, etc.

Conclusion

Industrial machines have made great progress. In the 60-70 centuries, where manual work was done, Now in the age of Industry 4.0, Machines not only work smartly and efficiently but take decisions as per situations.

Many industries are using additive manufacturing, Adaptive robotics, or other modern machines to increase productivity. Since researchers are still making machines better day by day, it will have a profound impact in the field of manufacturing in the future.

Great insights on the wide range of industrial machinery! I really appreciate how the post breaks down the classification of machines based on size, actuation methods, and their specific industry applications.