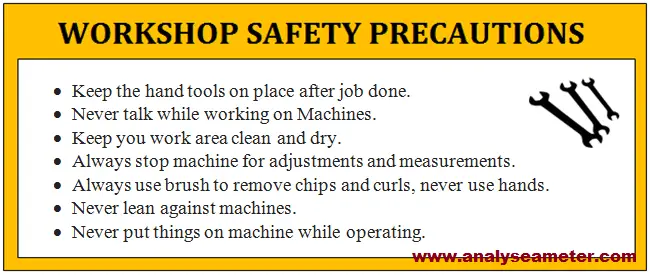

The following safety precautions or guidelines are generally adopted for every hand tool or cutting tool. They must be strictly followed for safety.

Safety Precautions For Different Hand Tools

Hammers

A hammer is a tool consisting of a weighted “head” fixed to a long handle that is swung to deliver an impact to a small area of an object. Hammers used to drive nails into wood, to shape metal (as with a forge), or to crush rock. Hammers are used for a wide range of driving, shaping, and breaking applications. Some safety precautions for operating hammers are as follows:

- Never operate the hammer unless its head is tightly fixed to the handle.

- Never strike two hammers together. The faces are very hard and the blow might cause a chip to break off.

- Never hold the hammer too far on the handle when striking a blow.

- Place the hammer on the bench carefully. A falling hammer can cause serious foot injuries.

- Use a claw hammer for pulling nails.

- Do not strike nails or other objects with the “cheek” of the hammer.

- Do not strike a hardened steel surface, such as a cold chisel, with a claw hammer.

Wrenches

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn nuts and bolts—or keep them from turning. Some safety precautions for operating wrenches are as follows:

- Always pull on a wrench. One can have more control over the tool if pulling instead of pushing and there is less chance of injury.

- It is a dangerous practice to lengthen the wrench handle for, additional leverage. Use a larger wrench.

- Choose a wrench that fits properly. A loose-fitting wrench may slip and round off the corners of the bolt head and nut.

- When using wrenches clean grease or oil from the floor in the work area. This will reduce the possibility of slipping and losing balance.

- Never hammer a wrench to loosen a stubborn fastener unless the tool has been specially designed for such treatment.

- Do not use wrenches that are bent, cracked or badly chipped or that have loose or broken handles.

- Discard any wrench that has spread, nicked or battered jaws or if the handle is bent.

- Use box or socket wrenches on hexagon nuts and bolts as a first choice, and open-end wrenches as a second choice.

Screw-drivers

A screwdriver is a tool, manual or powered, used for screwing and unscrewing screws. Some safety precautions for operating screw-drivers are as follows:

- Always wear goggles when re-sharpening screw-driver tips.

- Always use the correct tip of screwdrivers while screwing. The narrow or wide tip will damage the work.

- Screws with burred heads are dangerous and must be replaced or the burrs removed with a file or an abrasive cloth.

- Always use a screwdriver with an approved handle while working on electrical equipment.

- Do not force a screwdriver by using a hammer or pliers on it.

- Do not hold the workpiece against your body while using a screwdriver.

Files

A file is a tool used to remove fine amounts of material from a workpiece. Some safety precautions for operating files are as follows:

- Always use a file card to clean the file. Never use your hand.

- Never use a file without a handle.

- Never use a file as a hammer otherwise the file will break as Files are highly brittle.

- Never hammer on a file. It may shatter and chips fly in all directions.

- When using a file or a rasp, grasp the handle in one hand and the toe of the file in the other.

Saws

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is a very sharp tool & responsible for most minor accidents. Some safety precautions for operating Saw are as follows:

- Never check the sharpness of the blade by running fingers across the teeth.

- Never brush away the chips with your hand.

- Always wear goggles as all hard blades can shatter and produce flying chips.

- Always place the saw in that manner so that nobody accidentally reaches into the teeth when you pick it up.

Chisels

A chisel is a tool with a characteristically shaped cutting edge of the blade on its end, for carving or cutting a hard material such as wood, stone, or metal by hand. Some safety precautions for operating Chisels are as follows:

- Always hold the chisel in such a manner that the hammer blow may not miss the chisel to injure your hand.

- Edges of metal cut with the chisel are often sharp and cause bad cuts.

- Wear safety goggles and use a shield, when using a chisel, to protect yourself.

- Always remove the Sharp edges of chisels by grinding or filing.

Pliers

Pliers are the “opposable thumbs” for gripping, turning or twisting things. Some safety precautions for operating Pliers are as follows:

- Do not use pliers as a wrench or a hammer.

- Do not attempt to force pliers by using a hammer on them.

- When using the diagonal cutting pliers, shield the loose pieces of cut material from flying into the air by using a cloth or your gloved hand.

Taps and dies

Taps and dies are tools used to create screw threads, which is called threading. Some safety precautions for operating Tap and dies are as follows:

- Always use a brush to clean away chips formed by hand threading.

- Always wear goggles if the tap, die or threaded piece is to be cleaned with a compressed air gun.

- Always wash hands after using cutting fluid.

Vises

A vise or vice is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. Some safety precautions for operating Vises are as follows:

- When clamping a long workpiece in a vise, support the far end of the workpiece by using an adjustable pipe stand, sawhorse or box.

- Position the workpiece in the vise so that the entire face of the jaw supports the workpiece.

Reamers

Reamers are used to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. Some safety precautions for operating Reamers are as follows:

- Always remove all bars from the reamed holes.

- Never use hands to remove chips and cutting fluids from the reamer and work. Always use a piece of cotton or cloth.

Abrasives

Abrasives used for various cutting and grinding purposes. Some safety precautions for operating abrasives are as follows:

- Never rub fingers or hand across a piece polished by abrasive.

- Always remove all abrasive particles by washing them thoroughly after the polishing operation.

- Make sure that the Polishing machine is protected from the abrasive grains that fall from the polishing wheels during polishing.

Safety Precautions For Different Machine Tools

The following safety precautions or guidelines are generally adopted for different Machine tools for industrial safety.

Safety precautions for Lathe Machine

- Always be sure that all guards are in place before running the machine.

- Always clamp the work and tool properly with the correct size of work and tool holding device.

- Always stop Machine for making measurements or adjustments.

- Always keep the machine clean and never put things on it.

- Wear an apron or a properly fitted shop coat.

- Always use eyeglasses for eye protection.

- Never operate the lathe without knowledge of the proper procedure.

- Check the work frequently when it is being machined.

- Check the face-plate or chuck by hand to be sure that there is no danger of the work striking any part of the lathe.

- Stop the machine and remove chips & curls with pliers. Never use hands.

Safety precautions for Grinding Machines

- Cracked or worn grinding wheels must be replaced immediately.

- The grinding wheel must be properly balanced.

- Always ensure that no flammable materials are nearby that could be ignited by sparks generated by grinding wheels.

- Slowly move the table across the face of the wheel in a uniform manner.

- Before using a new grinding wheel, run it at the full speed to make sure that it is perfectly balanced.

- Never operate the grinding wheel beyond its bursting speed.

- Never put other things on the grinding table while grinding the job piece.

- Always wear goggles during grinding processes.

- Follow the manufacturer’s instructions for the correct use of the grinding wheels.

- Always use the face of the grinding wheel that is meant for grinding.

Safety precautions for Milling Machines

- Never put other things on the milling table while working on the job piece.

- Always stop the machine for making measurements and adjustments.

- Always stop machine for cleaning chips and curls.

- Never use hands to remove chips and curls.

- Never wear a watch, loose clothes while operating a milling machine.

- Never make contact with the revolving a cutter.

- When using cutting oil, prevent splashing by using appropriate splash guards. Cutting oil on the floor can cause a slippery condition that could result in operator injury.

- When installing or removing milling cutters, always hold them with a rag to prevent cutting your hands.

- Never use cracked or worn cutter for milling operation.

Safety Precautions For Welding Shop

- Always wear a proper face shield.

- Always wear close-toed shoes.

- Always wear a long-sleeved, non-flammable shirt.

- Always wear proper welding gloves.

- Always wear ear protection (earplugs or muffs) to prevent sparks from entering your ear canal.

- Never do a welding operation without eye protection. Always use specific welding eyeglasses.

- Always ensure that the weld area is free from all flammable materials such as flammable liquids, paper, etc.

- Before turning on a welding machine, ensure that there are no puddles of water on the floor around the welding machine.

- The welding machine must be dry, including the main box, the torch, the pedal, and the plug.

- Never touch Welded metal as it will remain hot for several minutes after it is welded.

- Gloves must be worn when welding and handling recently welded material.

- Cylinders must remain upright and never be placed horizontally.

- Cylinders must be secured with non-combustible material to an immovable object to prevented them from falling.

- Cylinders must be securely capped.

- Always mention on the cylinders the type of gas in it (i.e. oxygen, acetylene, etc.).

- Never weld the parts, which are coated with toxic material such as lead, cadmium, zinc, mercury, or paint.

- Acetylene gas should not be brought in contact with the unalloyed copper directly (except in torch) which may result in a violent explosion.

- Never mix the gases in one cylinder.

- Never use a leaking gas cylinder.

- Always keep welding cables free of grease and oil.

- prevent the non-insulated portion of the electrode holder from touching the welding ground or job-piece when the current is on.

- Always keep the body insulated from both the work and the metal electrode holder.

- Always turn the welding machine off when it is not in use.

Safety Precautions For Casting Shop

- One should use the mask to avoid excessive inhalation of the dust, which may cause serious problems to health.

- All foundry men should wear protective clothes, glasses, shoes, and gloves while handling molten metal for the casting process.

- Always be alert as severe burn injury can result from spillage of the molten metal.

- Always use proper ventilation to protect from molten metal fumes and gases that evolve from the mould during pouring.

- Wear respiratory protection while melting copper-base alloys (brass, bronze).

- Never touch hot moulds and castings.

- Metal added to heat during melt must be preheated.

- Sand Floor in the pouring area shall be clear of all objects not involved in pouring.

- Never look into exhaust during operation.

- always keep clean the work area.

Safety Precautions For stamping process

- Check the action of the clutch and brake. Correct ram cycle sequence according to the desired setting.

- Never operate press if the equipment does not function properly or will not recycle, after completing its selected cycle sequence.

- Look at the air pressure gauge to ensure that the air pressure is correct for operation.

- Inspect machine to verify that all guards are in place.

- Inspect the machine and remove all tools.

- Inspect all bolts and clamps to make sure they are tight and that die is securely fastened in press.

- Must aware of all safety warnings posted on or near machinery.

- Wear protective gloves and safety goggles when unstrapping sheet metal or coiled stock.

- Never wear loose clothing or jewelry when working on or around machinery.

- Do not place hand in the die area to remove the scrap, use the appropriate removal tool.

- Do not try to stop a workpiece as it goes through any machine.

- If jammed material cannot be removed with a hand tool, the motor and flywheel must be stopped, all power to press turned off and safety blocks inserted before any work is started.

- Do not place two pieces of material, one on top of the other (die-doubling, double-header) in the die as this can crack the die and seriously injure the operator.

- Stand to the side of the stock to prevent injury when cutting strapping.

- Stop the machine when not in use.

beneficial information for my students of metalwork.

I will share it with them. I love the layout as well.

Hello Clyde,

Looks like you are teaching in a college or university. It’s my pleasure that you liked our content. And it will be nice of you to share content with your students.

Thanks.

You made an interesting point when you talked about how it is important to avoid wearing clothing that is loose when operating a milling machine. In addition to that, I would imagine that it would be important to change the fluids in this machine on a regular basis. If it doesn’t have enough coolant, it will probably overheat and cause issues.