Want to know how Fluke 88v multimeter measures electrical parameters ? If yes then Click here

How to measure RPM with inductive pickup using Fluke 88V Automotive multimeter?

- RPM

is used for conventional 4-cycle engines.

is used for conventional 4-cycle engines. - RPM

is used for 2-cycle engines or waste spark DIS 4-cycle engines (count/revolution).

is used for 2-cycle engines or waste spark DIS 4-cycle engines (count/revolution).

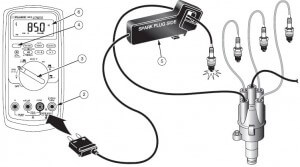

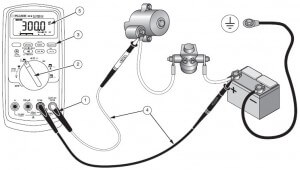

Steps for measuring RPM with inductive pick up using multimeter are:

- Turn the engine off before connecting or removing the pickup because the ignition system can create a potential shock hazard.

- Insert plug of Inductive Pickup in the input terminals of the multimeter.Insert -ve side of the plug in COM port and +ve side of the plug in RPM port.

- Turn rotary switch to

- For 4-cycle engines press

once to select RPM

once to select RPM  For 2-cycle engines and for DIS waste spark systems, press

For 2-cycle engines and for DIS waste spark systems, press twice to select RPM

twice to select RPM

- Clamp the Inductive Pickup to a plug wire near the spark plug.

- Turn the engine on and read RPM on the display. Turn the engine off before removing Pickup.

How to measure internal coil resistance of an ignition coil with Fluke 88V Automotive multimeter?

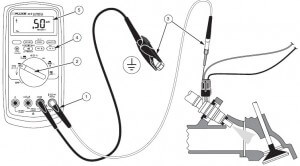

While measuring resistance always ensures that the contact between the probe and the circuit is clean because dirt, oil, dust etc will adversely affect the resistance measurement.

Steps for measuring internal coil resistance of an ignition coil are:

- Inside the com jack insert black lead and inside the

jack insert Red lead.

jack insert Red lead. - Turn rotary switch to

- To measure the resistance in primary windings touch the probes as shown in the figure.

- Reading on display indicates that the resistance value should be less than a few ohms

- To measure the resistance in secondary windings touch the probes as shown in the figure.

- Reading on the display indicates that the resistance value should typically be about 10K.

How to measure Pulse width on a port fuel injector with Fluke 88V Automotive multimeter?

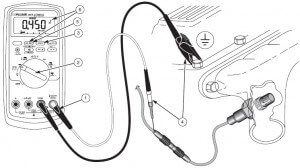

Steps for measuring Pulse width on a port fuel injector are:

- Inside the com jack insert the black lead and inside the

jack insert the Red lead.

jack insert the Red lead. - Turn the rotary switch to

- Connect the test leads to the injector as shown in the figure.

- To select pulse width press Hz% labeled button three times.The display shows ms.

- Start the engine and read the display.

How to measure voltages on a typical oxygen sensor using Fluke 88V Automotive multimeter?

Steps for measuring voltages on a typical oxygen sensor are:

- Turn the engine off and inside the com jack insert the black lead and inside the

jack insert the Red lead.

jack insert the Red lead. - To select 6v range press range labelled button.

- Make the connections as shown in the figure.

- Start the engine and press min/max labelled button to select min/max recording if the oxygen sensor is unheated.

- Press min/max labelled button to display maximum (MAX) oxygen voltage; press again to display minimum (MIN) voltage; press again to display average (AVG) voltage; press and hold down MIN/MAX for 2 seconds to exit.

How to measure starter circuit voltage drop using Fluke 88V Automotive multimeter?

- Inside the com jack insert the black lead and inside the

jack insert the Red lead.

jack insert the Red lead. - Tirn the rotary switch to mV or Temperature labelled button.If you are measuring voltage more than 600mV then 0L will appear on screen.To select 6V range turn the rotary switch to

- Press Autohold button.

- Touch probes across the connection to be measured.

- Note down the reading display on screen.

- Press Autohold button again to exit AutoHold.